Furnace Types: Computer Controlled

- Vacuum Furnaces with Nitrogen and Argon Pressure Gas Quench

- Integral Quench/ Endo Gas or Nitrogen Gas Atmosphere Furnaces with Oil or Intensive Water Quench

- Salt Baths

Case Hardening

- Precision Gas Carburizing

- Localized carburizing

- PLC controlled atmosphere

Carbon Restoration

Thermal Treatment for Plastics

Carbonitriding: Integral Quench Furnaces

Hardening Services: Quench and Temper

- Controlled Atmospheres

- Furnace to Air, Oil, Water Quench, or IntensiQuench®

- Vacuum/ Controlled Gas Quench – Nitrogen or Argon

- Neutral Salt Bath

- Automated Handling

- Austempering

- Marquenching

- Precipitation Hardening

- Artificial Aging

Annealing/Thermal Stress Relieving

- Full

- Homogenize

- Isothermal Anneal

- Subcritical Anneal

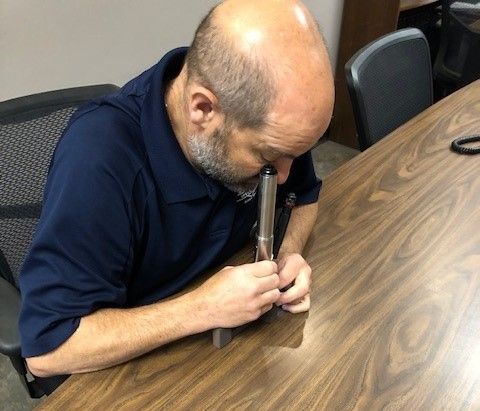

Quality and Inspection

- Gauging and Sorting

- Laboratory Testing

- Rockwell

- Superficial Rockwell

- Brinell

- Tukon Micro-Hardness - Knoop

- Metallographic Examination

- Metal Treating Institute trained Heat Treat Specialists

Cryogenic/Deep Freeze Treatments to -120°F

Additional Services

- Blast Cleaning

- Heat Treat for the Non-Heat Treater Seminars – presented at AST or Customer locations

- Metallurgical Consulting Services

- Specialty fixtures – Jig/ Flat Tempering

- Black Oxide available

- Pick-up and Delivery (in Ohio)

Akron Steel Treating Company

336 Morgan Avenue, Akron, OH 44311

P.O. Box 2290, Akron, OH 44309-2290

We deliver within Ohio. ![]()

Toll-Free: 1-800-364-ASTC (2782)

Phone: 330-773-8211

Fax: 330-773-0772

Email: info@akronsteeltreating.com

Follow Us:

Copyright © 2024 Akron Steel Treating. All rights reserved.